Finding flavor, incentivizing more

Scientists weigh in on “the next frontier” for beef quality research

Story and photos by Miranda Reiman

Life is not always heads or tails, black and white or pass-fail.

When it comes to beef, certain traits, like tenderness, are easier to quantify than others.

“Beef flavor is very complex. It’s not one attribute, but many, many flavor notes,” said Bridget Wasser, executive director of meat science for the National Cattlemen’s Beef Association (NCBA). “There are a lot of things that can go right and there are a lot of things that can potentially go wrong.”

Each consumer views it differently.

“We have to make sure we find a way to give it to everyone, all the time, and so consistency of the product comes into play,” Wasser said, during her Cattlemen’s College presentation earlier this month.

She told 2017 Cattle Industry Convention and NCBA Trade Show attendees the beef community has made marked improvements in tenderness over the past few decades, “so the good news is that it allows us to focus on some of these other eating attributes.”

Phil Bass, meat scientist for the Certified Angus Beef® (CAB ®) brand, was in the audience and agreed. Projects are starting to encompass some of these harder-to-measure traits.

“We’ve researched tenderness quite extensively and beef flavor is the next frontier, the next area that we really need to focus on,” he said later.

Lipids, carbohydrates and proteins that make up beef have the greatest influence on flavor. Lipids, or fats, are species-specific, differing in both amount and fatty acid composition. That’s why beef doesn’t taste like pork or poultry.

“We’ve always known that fat contains the specific flavor compounds; more of it will express more of those flavors,” Bass said. “The grain-finished, beef-fat flavor is highly desirable to the palate.”

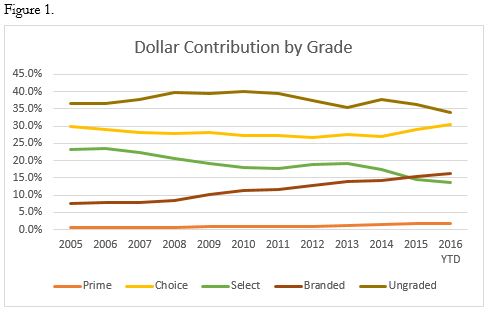

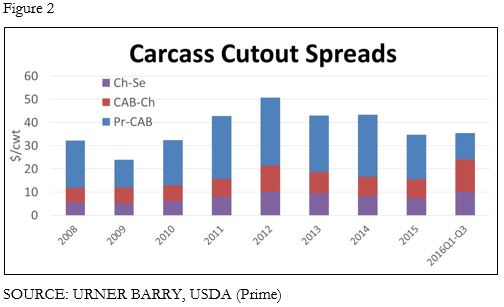

Recent work validates the USDA quality grading system’s ability to predict eating satisfaction, along with the CAB brand’s 10 carcass specifications, Bass said.

“Marbling is something we hang our hat on as a beef industry,” Wasser said, because it gives the protein its “buttery, beef-fat” notes. “That’s a very positive flavor. It’s something consumers respond very positively to and that’s why it has a lot of credence in our quality grading system and the valuation of our beef carcasses.”

A Beef Checkoff project recently added more precision to sensory science, by developing a beef lexicon, or a dictionary of sorts for 38 attributes.

“How can you pick them out if you don’t know what an individual flavor note is?” Wasser asked.

Researchers train panels using this common terminology, and use participants as instruments in both discrimination and descriptive research.

Scientists get better results by either increasing the numbers in a sample size or limiting the variance, Bass said.

“When you have a trained sensory panel, you don’t need as many,” he said. “The better you can control the variation, panelist to panelist, the better you’ll be able to find the differences.”

Oftentimes, training for beef-fat flavor involves sampling a Prime strip steak versus a standard or very low Select option.

“It’s very important to have these folks calibrated,” Bass said.

Trained panels will detect flavors and note intensity, but larger consumer panels will determine its acceptability level.

“It’s not until you put it into the mouth of the consumer that you see, is this economically viable? Is this applicable to the end-user?” Bass said. “Time and time again, consumer research looking at beef marbling shows more marbling is better. It gives better flavor. It contributes to tenderness. It maintains juiciness.”

That’s why it’s getting the attention of the entire beef community.

“Consumers of your product have very high expectations,” Wasser told the cattlemen. “That gives us a common goal to work towards.”

You may also like

Goodbye ocean, hello involvement

If there’s ever a chance to skip class and travel to a beach state…count me in.

Buzz words still tell the stories

Adding value. Consumer confidence. Growing demand. Those are popular (and thus often overused) phrases, but they are central to what we do here at CAB.

Cattle Industry Convention sets mood

Call it optimism or happiness or a light-hearted spring in your step….the term doesn’t matter, last week at the Cattle Industry Convention and Trade Show you could feel it.