Carpenter Cattle Company Recognized for Feeding Better Cattle Better

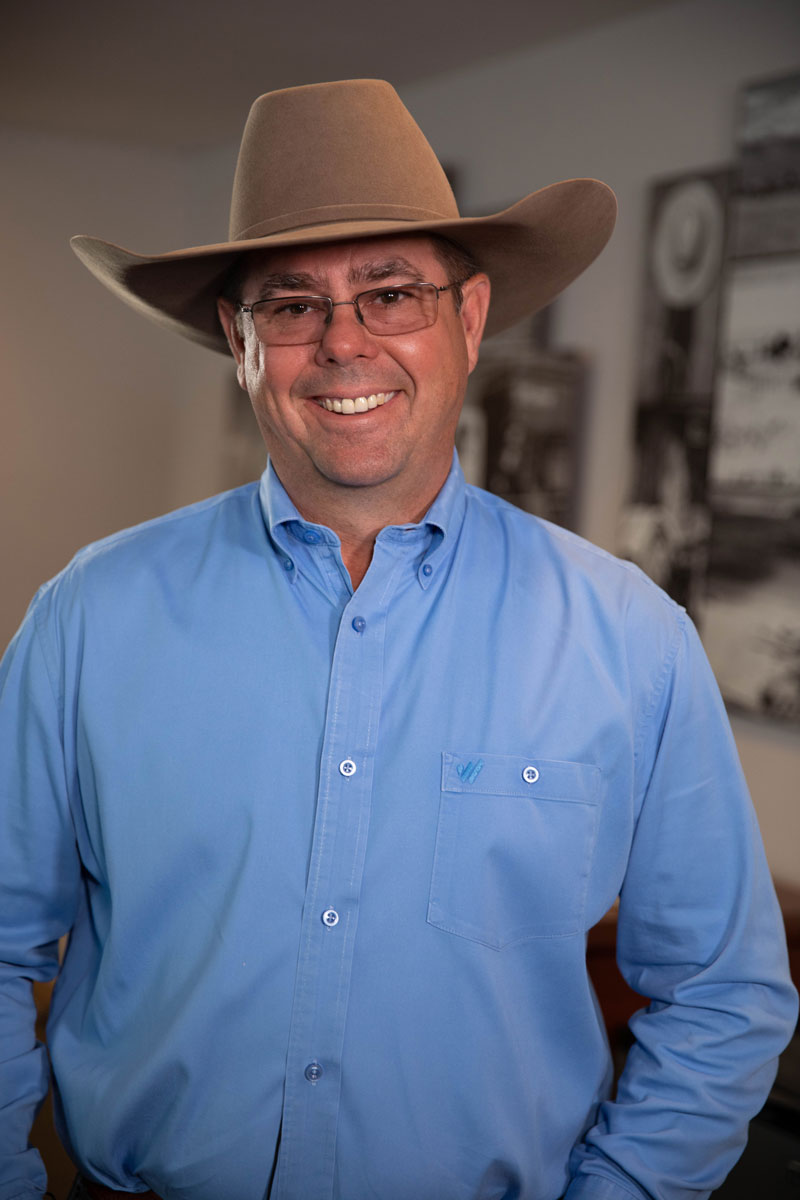

Kansas feeder earns the 2024 CAB Feedyard Commitment to Excellence Award.

by Kylee Sellnow, senior content manager

September 2024

Not everyone is cut out to be a cattle feeder. It’s an art and a science that comes with a need to overcome risk. Wayne Carpenter fed his first pen of steers in 1980 and lost money. But he stuck with it.

Today with their sons’ families, he and wife Leisha run the 15,000-head-capacity Carpenter Cattle Company.

The Brewster, Kansas, yard still has the same priorities it started with at 1,000 head: cattle care, facility management, profitability and commitment to high-quality beef. Learning and adjusting over time serve to temper the risk.

“We have to be aware and listening to all segments of the industry, including chefs, retailers and the consumer, we have to know what they do and don’t want,” Wayne says.

This dedication to feeding the best beef earned Wayne and his family the 2024 Certified Angus Beef (CAB) Feedyard Commitment to Excellence Award. They received their award in Verona, New York, at the brand’s Annual Conference in September.

An Art

Bunks are clean, waterers clear and cattle quiet. Not a day goes by that a pen isn’t fed within an hour’s deviation at the Carpenter yard.

You can find Wayne himself in the feed truck most mornings.

“It’s more than dumping feed and calling it good,” he says. “The little things in the yard, the ones you don’t think about here and there. Those add up to affect your bottom line.” The challenge drives him.

“Wayne’s not a quitter,” Leisha says. “From getting cattle marketed right to adjusting for the weather we have, he’s not afraid to take a chance to grow and try something different.”

The Carpenters have positioned their yard for success with all team members Beef Quality Assurance (BQA) certified and the business backed by Micro Technologies precision feed management.

“Animal health, feed inventory, feed truck scales, GPS, billing, all of it is tracked through one system which has made our life a lot easier,” Wayne says. “We can run any report we need for our veterinarian or nutritionist—you name it, we can analyze it. It’s made us better.”

His customers recognize that meticulous care.

Wayne McKinney runs a cow-calf operation near Weskan, Kansas, and has retained ownership of calves through Carpenter Cattle Company.

“He’s not a manager that is 200 miles away and has somebody else running it,” McKinney says. “He’s available at any time and can tell me how my cattle are doing. He’s a progressive go-getter, always making improvements.”

The Carpenter approach to embracing innovation and technology to improve results wins many admirers.

“Not only does Wayne do a quality job with the animals and the economics of the business, but the relationship is top shelf as well,” Keith Burcamp says.

The stocker and backgrounder at Cottonwood Feeders, Cunningham, Kansas, tips his hat to the business ethics.

“I don’t know many people who work harder,” Burcamp says. “I really appreciate his guidance. He’s always honest with me; he’s consistent and his character is top-notch.”

A Science

Carpenter commends the Angus breed for adding to the producers’ toolbox with genomics and data that point the way to CAB grid premiums.

Those tools cut down on guessing when cattle are finished and how long it will take to improve them.

“We used to eyeball it or maybe look at our grids and figure it will be two years before it gets better,” Wayne says. “Now, we’ve sped that up.”

Before joining U.S. Premium Beef, the Carpenters sold pens of finished cattle on the cash market, all for the same average price. But once they started to get individual carcass data back and saw the greater value of high-quality beef, they leaned into grid marketing. They haven’t looked back.

“If it wasn’t for grids improving carcass quality and putting that quality in front of the consumer, we wouldn’t have the demand for our product today,” Wayne says. “It’s made us better cattle feeders.”

He says it takes feeding the right kind of cattle to make the most out of the grid, and they’ve been lucky to have some great partners that have made it a successful business for all of them.

“You’ve got to have quality pounds,” Wayne says. “The whole industry is pushing over 80% Choice and Prime, and I’ve got to compliment the cow-calf side of this business. They don’t always get the recognition, but it all starts there with quality genetics. We’re just a piece of the chain here at the feedyard, and it all starts at the ranch and setting calves up right.”

Risk Overcome

Wayne grew up in a family of dryland farmers and ran a few cow-calf pairs with his dad. After feeding out his first pen of steers, however, he was hooked.

“My dad told me one day, ‘You’re going to go broke feeding cattle,’” Wayne chuckles. “And he was right. We’ve been broke three times. We always come back. Like I always told him, ‘When you were a wheat farmer and you got hailed out, did you quit? No, you kept going.’”

Success over the long term means learning from setbacks in a series of calculated risks.

“Businesses take time to grow and mature. Just make sure you enjoy what you’re doing.”

For Wayne and Leisha Carpenter, the risk has paid off.

This story was originally published in the Angus Journal and Angus Beef Bulletin.

You may also like

Better Cattle Bring Opportunity

Cattle keep getting better, but that doesn’t mean producers should slow down progress. That’s what attendees took home from the 2025 Feeding Quality Forum. It’s call to action for the entire beef industry. Better cattle, yet new and old challenges for each segment.

Future Beef Leaders Receive $100,000

The Colvin Scholarship Fund awarded 27 students a combined $100,000 for their pursuit of innovation, growth and leadership in the beef industry. Each recipient is actively pursuing a career in production agriculture, industry research or other agricultural endeavors. With their aspirations for success in the beef business, they are continuing the legacy of Certified Angus Beef’s (CAB) co-founder and long-time executive director, Louis “Mick” Colvin.

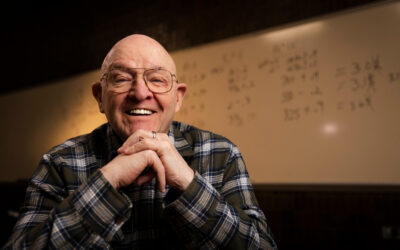

Purpose Follows Passion

A chance opportunity. A change in career direction. And meat science was changed forever. Dr. Gary Smith originally had no plans to become a meat scientist. But thank goodness he did.

It’s not, as Wilson would put it, “hippy woo-woo.” He has the data to prove it works, boiling down the economic input into gains and head-days in pasture. Limited input, maximum production output tracked on a per-head basis gets the most for his resource dollar.

It’s not, as Wilson would put it, “hippy woo-woo.” He has the data to prove it works, boiling down the economic input into gains and head-days in pasture. Limited input, maximum production output tracked on a per-head basis gets the most for his resource dollar.