CAB export expert on quality

by Miranda Reiman

Cattlemen know overseas markets are important to their bottom line. Maggie O’Quinn, of Certified Angus Beef LLC (CAB), recently reminded producers how significant they are to exporters.

Speaking at the Georgia Cattlemen’s Association annual convention March 31, the CAB executive account manager for Latin America and the Caribbean explained the value of trade relationships, the logistics of exporting, and why producers should care.

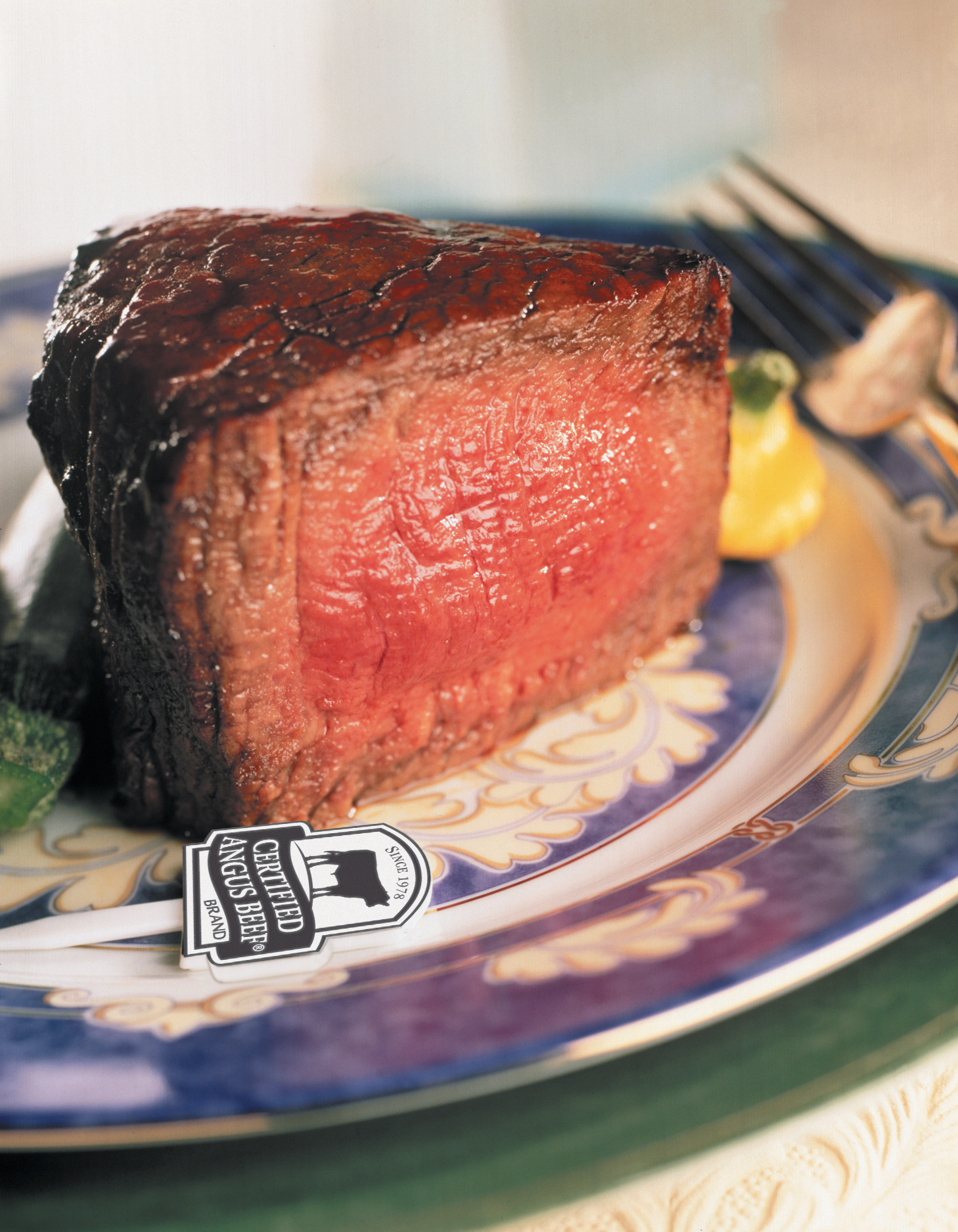

“You are the design engineers for the No. 1 thing that we export: quality,” she said. “Quality is our unique selling proposition.”

The U.S. is not a low-cost supplier like some competing countries.

“We are not going to be all things to all markets, but U.S. beef is known for quality from Dubai to Tokyo to Aruba,” said O’Quinn, who serves on the 2011 U.S. Meat Export Federation (USMEF) executive committee.

The quality niche is an import role to fill, because strong international demand last year added a record $153.09 per head to the value of each harvested animal, she said.

“They’ll use products that aren’t big sellers domestically,” O’Quinn said. “Who eats liver? My granny made liver and onions and I personally don’t like it, but thanks to Egypt and Russia livers add $6 per head in value.”

Japan and Korea are big markets for short ribs, so opening those back up has added more than $20 per head.

“The chuck, the round and the short plate now account for 52% of the export value of each animal,” O’Quinn said. “That’s compared to 42% coming from the middle meats.”

CAB is in 69 countries, and international sales represent more than 10% of the company’s total tonnage, but staff members are still working to introduce other places to high-quality U.S. beef.

“We’re truly developing the market for fresh beef in Trinidad,” she says. “Beef, in their minds, is this frozen, awful stew meat. It’s a challenge to shift from that mentality to get an upscale presentation and correct merchandising with refrigeration.”

That’s what O’Quinn and her team work on every day, but that’s just one of the challenges. The distributors and exporters that they work with face many hurdles in getting product from point A to point B.

O’Quinn shared an example: “To get from Tyson Foods, in Dakota City, Neb., to Faisal al Nusif in Dubai, United Arab Emirates, it takes a long, long time and a lot of work.”

It takes two weeks for one load of tenderloins to get from the packer to a distributor in Atlanta.

“The minute the product is received, the box label is sent for translation from English to Arabic,” she said. “Then the distributor has to physically open each box and apply an Arabic label to each piece of beef. It requires 12 additional people to handle this work and it takes two days.”

After all that, it’s inspected by USDA and receives export approval. The container, accompanied by letters and forms from USDA and the Georgia Health Department, is frozen and then loaded for shipping to the Middle East.

“It’s loaded on a boat and the first stop is Port Said in Egypt, then through the Suez Canal into the Red Sea, around the Arabian Peninsula, through the Strait of Hormuz and eventually into the Persian Gulf to the port city of Dubai,” O’Quinn said.

The product spends anywhere from 24 to 35 days on the boat, so by the time it reaches distribution channels in Dubai it’s probably already 50 days post-harvest.

“The freight cost is about $4,500 per container,” she said. “Then there’s the cost to legalize the documents, for those extra employees, the cost of the stickers, insurance, special storage and even extra financing costs.”

That’s why the going menu rate for a 10-oz. Certified Angus Beef ® (CAB®) tenderloin in Atlanta is $35, compared to $65 in the world’s only seven-star hotel, Burj al Arab (the Arabian Towers).

The reason it’s worth that goes back to the inherent quality, O’Quinn said.

“You have a role in ensuring that, and in our ability to market quality,” she said. “Thank you for all you do.”